Mr. Kazuchi Isokawa from the Sales Division of UNIX Co., Ltd was recently interviewed by our partner COMNET. In the interview, he provided insights into the GCC LaserPro S400 laser engraver. He shared with us his reasons for adopting our laser engraving machine, their applications, and the benefits they have experienced.

Company Name: UNIX Co., Ltd

Major Business Items: Manufacturing, sales and import/export of plastics and metals. Sales of machinery and equipment for eyeglass manufacturing

Location: Fukui-ken, Japan

GCC Products: GCC LaserPro S400 laser engraver (80W)

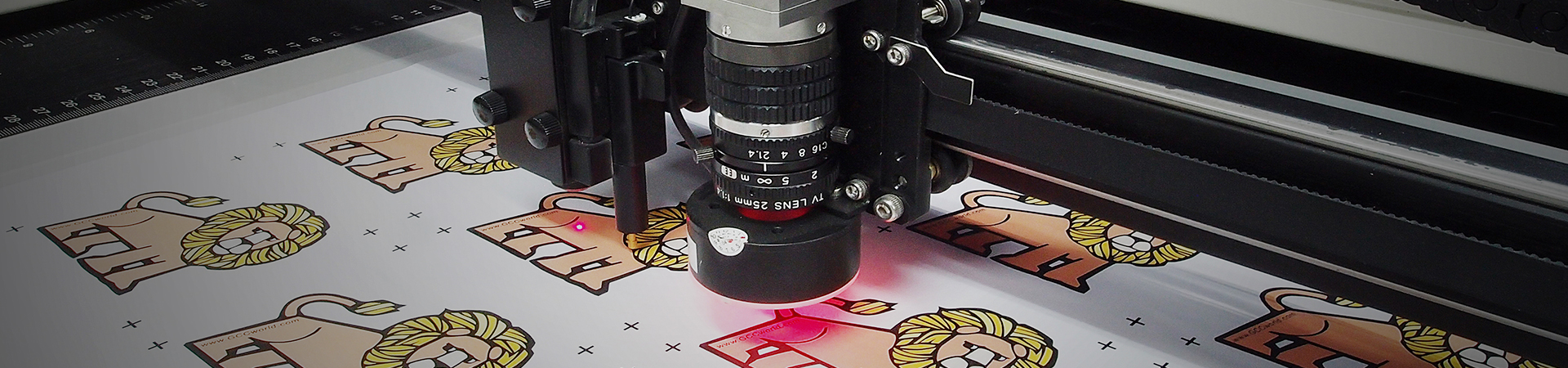

How did the GCC S400 speed your production time?

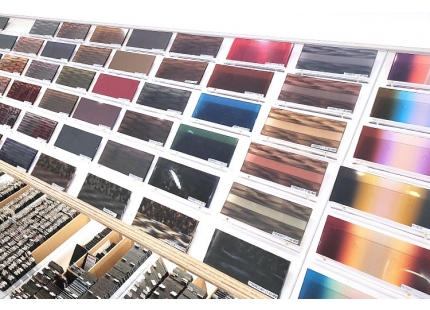

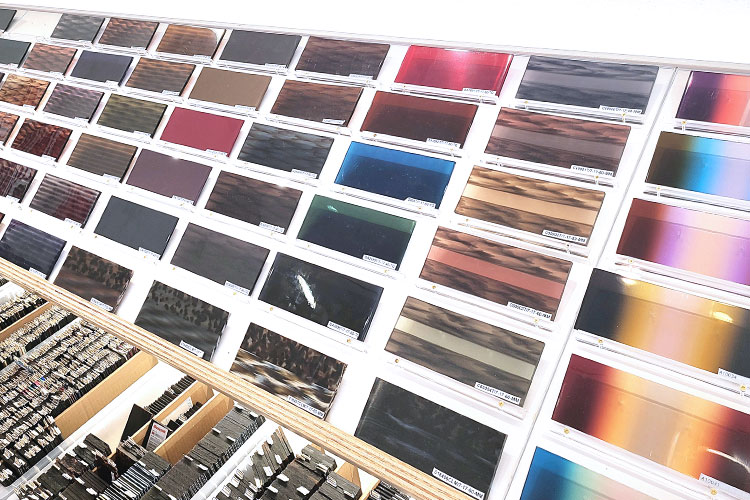

Our company specializes in selling materials such as plastic and metal, covering a wide range of products from components to secondary materials, particularly related to the production of eyeglasses. We have a strong advantage in offering an industry-leading selection and the ability to develop and manufacture original eyeglass materials.

Primarily for eyeglass planners, developers, and designers, we present samples for material selection. However, a significant challenge we faced was the considerable amount of time required for material selection.

After selecting the materials, we proceeded to create prototypes and await final checks before placing orders. As we outsourced prototype production to processing companies, even for a short turnaround, it took several days for delivery.

While a single successful prototype streamlined the process, any changes or adjustments required waiting for the completion of each new prototype. This resulted in time-consuming delays whenever modifications were needed.

Samples of materials used for glasses

What are the reasons and main considerations for introducing the laser machine?

The decision to consider and introduce a laser engraving machine arose during the renovation of our company building. Along with the building renovation, we searched for ways to improve business through capital investment and found out about a laser engraving machine that is suitable for creating prototypes.

We recognized that in-house prototyping could significantly reduce lead times, and the versatility of laser engraving machines in handling a wide range of materials appealed to us. Considering these factors, we made the decision to implement the GCC LaserPro S400 laser engraving machine.

The decisive factor for choosing the GCC LaserPro S400 was its excellent compatibility with materials such as acetate and other plastics in terms of size and usage.

Model Implemented: Laser engraving and cutting machine GCC LaserPro S400

Eyeglass Frame Samples

What Results Follow Laser Machine Installation?

After implementing the laser engraving machine, we gained the ability to create prototype samples on the spot right after material selection. Customers appreciate being able to "confirm the compatibility of design and material instantly."

As a result, the time required from material selection to placing an order has been reduced from up to a month to just a few days. This shortened lead time in eyeglass manufacturing allows us to be more flexible in meeting customer deadlines and requests.

After the introduction of the laser engraving machine, we are now able to create eyeglass samples on the spot.

What are your future prospects for the laser business?

We believe that acetate, the material we use for eyeglasses, possesses exceptional design potential that extends beyond eyeglasses. Considering this, the introduction of the laser engraving machine has inspired us to venture into product development in various fields and industries.

Initially, we plan to create high-value products such as accessories (considering the popularity of dinosaurs in Fukui Prefecture, dinosaur-themed accessories) as well as Shogi (Japanese chess) and mahjong tiles. Additionally, we are open to collaborating with companies that specialize in accessory manufacturing, which could significantly broaden the scope of our business.

Our goal is not only to enhance our existing business but also to utilize the laser processing machine for innovative business expansion. We are excited to explore new opportunities and fully leverage the capabilities of the machine in these endeavors.

Products made from acetate

made from acetate.jpg)

Shogi (Japanese chess) made from acetate

To read the original article, please? click here.

*Please refrain from reproducing or distributing this article without obtaining permission from GCC.

Introduced laser engraving and cutting machine:

S400 Dual Laser System Laser Engraver

Unlimited laser engraver and engraving machine, the best ever, beyond expectation product

Specification

| Working Area | 1016 x 610 mm (40 x 24 in.) |

| Z-axis | 280 mm (11 in.) |

| Wattage | CO2 Laser 40W~120W | Fiber Laser 20W~60W |

| Max. Working Speed | 140 IPS |

We are happy to answer your questions about any laser products and processing. If you want to learn and do more with GCC LaserPro lasers, we invite you to see our laser engraving and cutting applications videos where you will find out how they physically work and are done.

Further reading:

➤SmartEYES™ CCD is Your Time-Saving Tool to Boost Productivity

➤Discover the Power of Laser Engraving

➤Tips and Tricks: Acrylic Cutting with Your Laser Engraver and Laser Cutter