Mr. Minomiya Masatomi, Director and Production Manager of SASAKI Kogei Co., Ltd introduced GCC LaserPro laser engravers, the S400 and SPIRIT GLS. He graciously shared with us the reasons for choosing the GCC laser machine, its diverse applications in laser engraving and cutting, and the benefits they have experienced.

Company Name: SASAKI Kogei Co., Ltd

Major Business Items: Manufacturing and selling of wooden crafts

Location: Hokkaido, Japan

Facebook

GCC Products: GCC LaserPro laser engraver S400 (80W) and Spirit GLS (80W)

What issues did you have before introducing the laser engraving machine?

Our company is a manufacturer specializing in the production and sale of wooden crafts. Even before introducing laser engraving machines, we had developed and sold 500 different off-the-shelf products.

While engaging in sales and distribution of these 500 products to nationwide wholesalers and retailers, we identified challenges related to 'differentiation from other companies' and 'initiatives to create originality.' To address these two challenges, we recognized the need for new business expansion and began exploring the introduction of machinery and equipment.

Wooden carp streamer

Laser engraving process is also used to put names on the boxes.

What are the reasons and main considerations for introducing the laser machine?

The decision to introduce the laser engraving machine was driven by its high mechanical performance, user-friendly operation, and excellent after-sales support. The decisive factor, in particular, was the quality of the after-sales service.

During the consideration phase, we attended various trade shows and visited several manufacturers to gather information. We had discussions and witnessed demonstrations. Among various manufacturers and companies, COMNET stood out as the one that provides the most reassuring and reliable customer support for GCC LaserPro lasers.

Wooden hina dolls

Utilizing laser engraving for cutting and printing parts.

What results follow laser machine installation?

Since the installation of the GCC LaserPro laser engraving machines,our production output has increased by 15%. The demand for custom projects and OEM projects has also risen, resulting in a 7% increase in sales.

We not only use laser engraving for personalized processing on products but also leverage it for cutting wood parts. The laser cutting of parts has seen a significant increase in production volume, comparable to the use of the NC router we were using before introducing the GCC LaserPro.

Moreover,the versatility of GCC LaserPro laser engravers allows us to perform a wide range of processing tasks, making them indispensable machines for our company in product development.

Setting up boxes to be engraved with a name

The SPIRIT GLS is available in heights up to 177 mm.

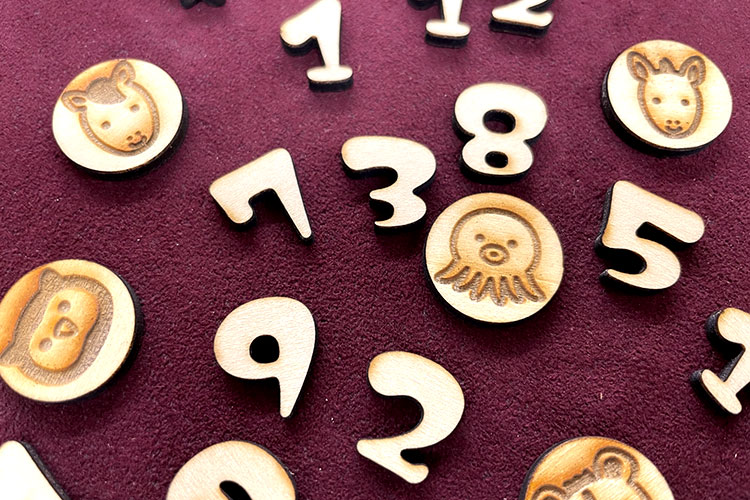

Works by SASAKI's laser engraving & cutting

We add value to the original products by incorporating brand logos and personalization. For OEM products, such as corporate novelties, we specialize in custom engravings such as logos and commemorations like 'XX th-anniversary' items.

Additionally, to differentiate ourselves from other companies, we utilize laser engravers in holding woodcraft workshops. This not only enhances our product offerings but also contributes to creating a unique and engaging experience for our customers.

What are your future prospects for the laser business?

Currently, we have two laser engraving machines which are engraving and cutting with thin materials.

In the future, we aim to broaden the scope of product development by introducing machines capable of handling materials that are challenging for our existing laser engraving machines, such as thick sheets and artificial marble.

Our goal is to leverage the strengths of each machine, combining them effectively to achieve further differentiation from other companies in our industry.

To read the original article, pleaseclick here.

*Please refrain from reproducing or distributing this article without obtaining permission from GCC.

Introduced laser engraving and cutting machine:

We are happy to answer your questions about any laser products and processing. If you want to learn and do more with GCC LaserPro lasers, we invite you to see our laser engraving and cutting applications videos where you will find out how they physically work and are done.

Further reading:

➤Exploring the Versatility of Laser Engraving: Capabilities and Materials

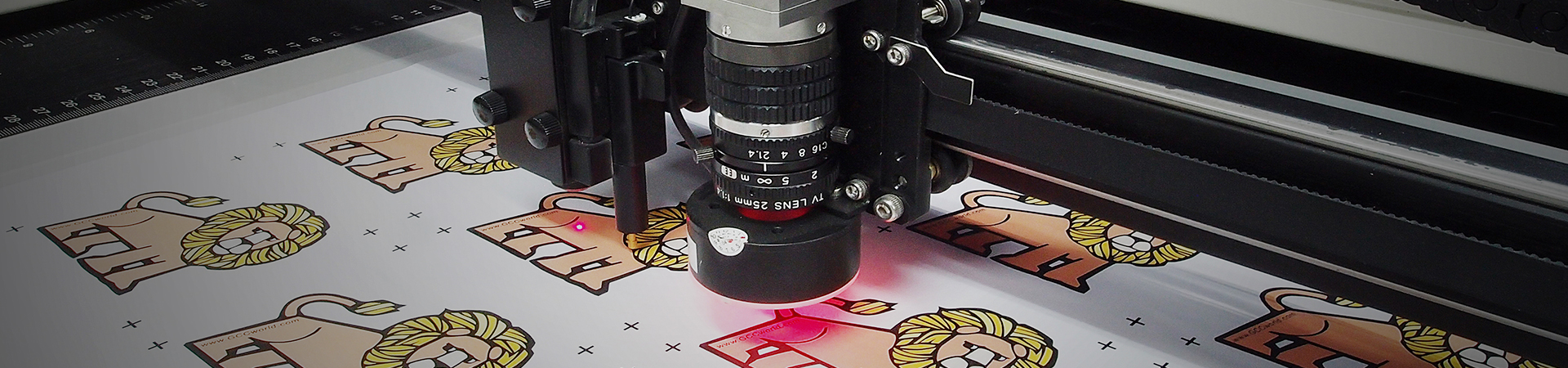

➤SmartEYES™ CCD is Your Time-Saving Tool to Boost Productivity

➤Discover the Power of Laser Engraving